One critical aspect of fire safety in any commercial building is ensuring that the fire protection systems are in working order, especially the fire pump. Understanding how a fire pump operates and the maintenance it requires can help you ensure your building complies with local fire codes, avoid costly penalties, and, most importantly, protect lives.

What is a Fire Pump?

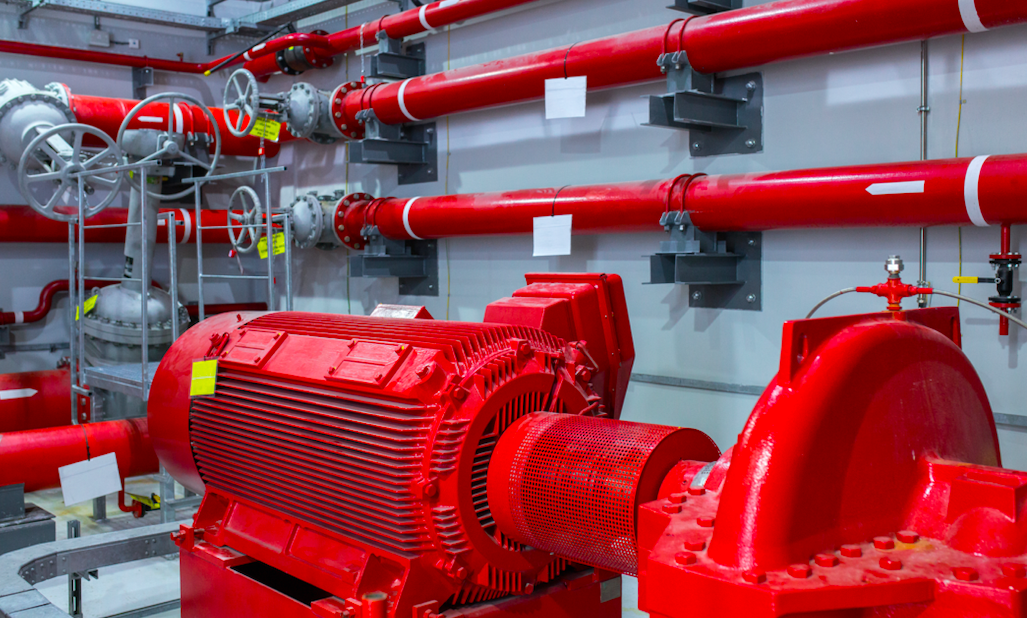

A fire pump is a crucial component of a building’s fire suppression system, designed to increase the water pressure in sprinkler systems, standpipes, or fire hydrants. When a building’s normal water supply isn’t sufficient to support fire protection systems—such as in high-rise buildings or structures located far from municipal water supplies—a fire pump ensures that water flows at a high enough pressure to suppress fires effectively.

There are several types of fire pumps, including:

- Centrifugal pumps: The most common type, where water is drawn into a spinning impeller, increasing water pressure.

- Vertical turbine pumps: Typically used when the water source is located below the pump, such as in a reservoir or well.

Note: Centrifugal pumps can be diesel driven or electric while vertical turbines are electric driven.

How Does a Fire Pump Work?

In the event of a fire, when the sprinkler system activates, the water pressure in the pipes drops. This drop in pressure triggers the fire pump to start. It draws water from an external source (such as a municipal supply or water storage tank) and sends it into the sprinkler system at a much higher pressure. This high-pressure water helps the sprinklers to cover more area and deliver a consistent flow, suppressing or extinguishing the fire until emergency services arrive.

The fire pump is activated automatically, often by pressure-sensing devices, though it can also be turned on manually. It’s important to note that fire pumps are not operational unless the system detects a loss in pressure, meaning they are always on standby, ready to engage when needed.

The Importance of Regular Maintenance

Fire pumps are vital for the safety of your business, but they can only fulfill their role if they are well-maintained. Regular maintenance ensures that the pump will operate correctly during an emergency and can prolong its lifespan. Neglecting fire pump maintenance could lead to mechanical failures, putting your property and lives at risk.

According to fire safety codes, such as the National Fire Protection Association (NFPA) standards, fire pumps must be inspected, tested, and maintained on a regular basis. Here’s a closer look at the types of maintenance required:

-

Weekly Testing and Inspections

A weekly visual inspection helps ensure the pump remains in a state of readiness. You or your fire protection contractor should check:

- Control panels: Ensure they are in the correct position and ready to activate.

- Battery voltage(for diesel engines): Ensure that the battery is charged to start the pump if needed.

- Water pressure readings: Confirm that the pressure is within the acceptable range when the system is idle.

- General cleanliness: The pump room should be free from dust, debris, or any obstructions.

- Automatic start: Ensure that the fire pump activates when the pressure drops.

- Churn Test– Diesel driven pumps will be ran for 30 minutes per week.

- Diesel engine performance(if applicable): Check fuel levels, engine temperature, and oil pressure to ensure the pump is ready to perform

- Flow rates and pressure: Confirm that the pump is delivering the correct flow rate and pressure as per the manufacturer’s specifications.

- No unusual noises or vibrations: Any strange sounds can indicate mechanical issues, which must be addressed immediately.

-

Monthly Tests and Inspections

A monthly test run ensures that the fire pump will perform when needed. During this test, the pump should be operated for at least 30 minutes. Here are key aspects to check:

- Control panels: Ensure they are in the correct position and ready to activate.

- Water pressure readings: Confirm that the pressure is within the acceptable range when the system is idle.

- Automatic start: Ensure that the fire pump activates when the pressure drops.

- General cleanliness: The pump room should be free from dust, debris, or any obstructions.

- Electric Driven Motor– Ten minute Churn test to be completed.

- Flow rates and pressure: Confirm that the pump is delivering the correct flow rate and pressure as per the manufacturer’s specifications.

- No unusual noises or vibrations: Any strange sounds can indicate mechanical issues, which must be addressed immediately.

-

Annual Maintenance

An in-depth annual inspection and maintenance of your fire pump should be conducted by a certified technician. This inspection typically involves:

- Full operational testing: The pump is operated at full capacity, simulating real fire conditions.

- Gauges and meters calibration: Ensuring accurate readings on all pressure gauges and flow meters.

- Lubrication of moving parts: Proper lubrication ensures that mechanical parts remain in good condition and function smoothly.

- Impeller inspection: The impeller, which moves water through the pump, should be inspected for signs of wear and tear.

- Electrical connections: For electric fire pumps, technicians will ensure that all connections are secure and functioning properly.

-

Corrective Repairs

During inspections and tests, any issues found—such as worn-out seals, defective pressure gauges, or leaks—must be addressed immediately. Corrective repairs can range from simple fixes, like replacing a worn valve, to more extensive work, such as rebuilding parts of the engine. Prompt action on these repairs is critical to ensure your fire pump is reliable during an emergency.

Why Fire Pump Maintenance is Essential for Business Owners

There are several reasons why maintaining your fire pump is crucial for Georgia business owners. Among these include:

- Compliance with regulations: Georgia follows the NFPA guidelines and local fire codes, requiring routine inspections, testing, and maintenance of fire pumps. Failure to comply can result in hefty fines and may invalidate your insurance policy.

- Avoiding operational downtime: A well-maintained fire pump can prevent costly disruptions. If your fire protection system fails to function during an emergency, not only do you face significant property damage, but your business could be forced to close for extended repairs.

- Protecting lives: Fire safety is ultimately about protecting lives. Your employees, customers, and the surrounding community depend on your fire safety systems to function when they’re needed most. A malfunctioning fire pump can lead to tragic consequences.

- Saving money over time: Regular maintenance reduces the likelihood of costly emergency repairs or full system replacements. It also extends the life of the pump, maximizing your investment.

Fire Systems, Inc.

For business owners, understanding how a fire pump works and the importance of regular maintenance is crucial for ensuring fire safety. These systems are complex but reliable, provided they receive the necessary attention. Through weekly inspections, monthly tests, and annual maintenance, you can ensure that your fire pump will perform as expected in an emergency—protecting your business, your employees, and your livelihood. Don’t wait until it’s too late; prioritize fire pump maintenance to ensure the safety and compliance of your commercial property.

Fire Systems, Inc. is an Atlanta-based fire protection company with over 35 years of experience in fire protection. Our family-owned, family-operated business is dedicated to your safety. We provide fire protective services to a variety of industries, including fire sprinkler, fire alarm, suppression, and more. Let us help protect your business from fire. Trust the professionals at Fire Systems, Inc. and call us at 770-333-7979 or visit our website to find out how we can help.